A pinch of polymer-munching enzymes may make biodegradable plastic packaging and forks actually compostable.

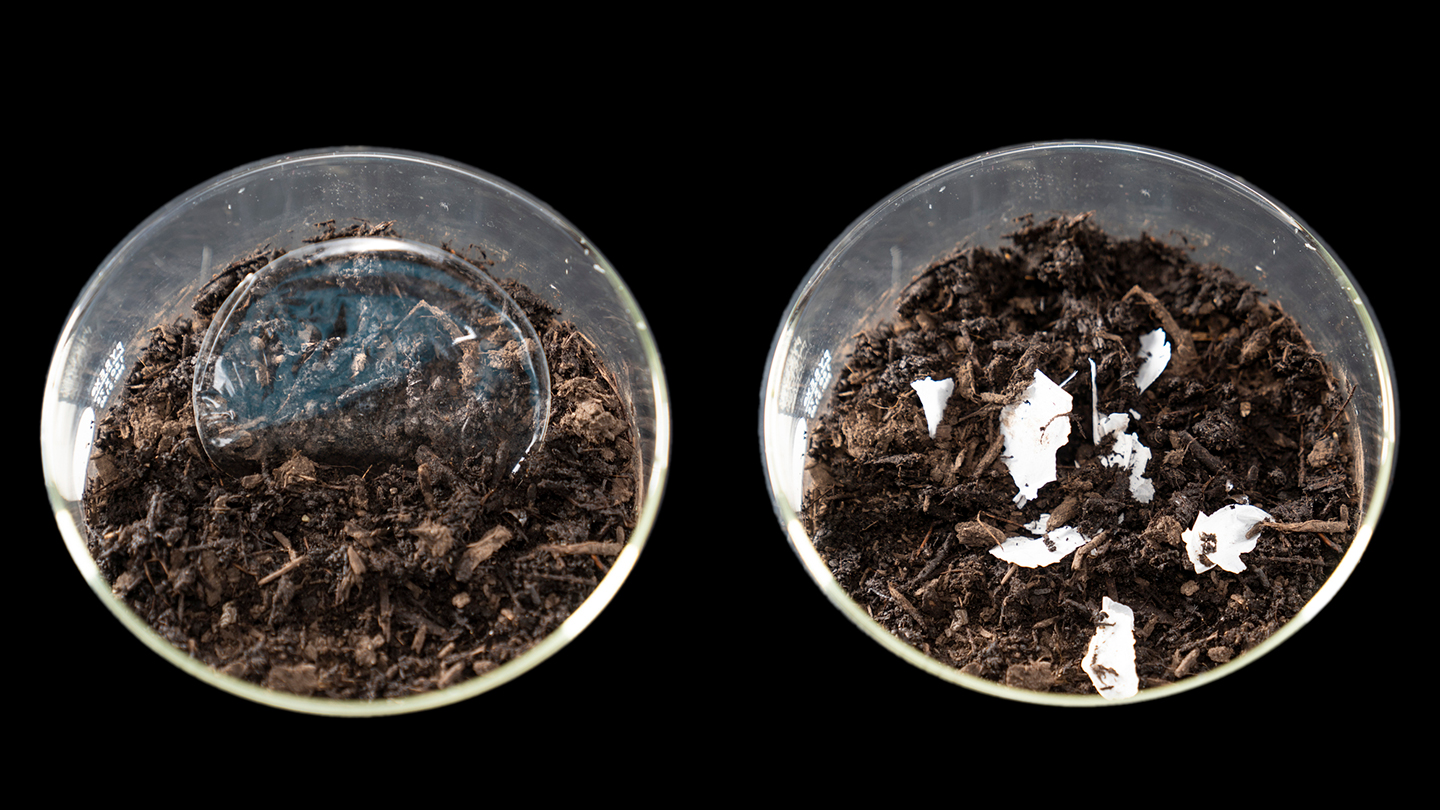

With average warmth, enzyme-laced movies of the plastic disintegrated in standard compost or plain tap water inside days to weeks, Ting Xu and her colleagues report April 21 in Nature.

“Biodegradability does not equal compostability,” says Xu, a polymer scientist at the University of California, Berkeley, and Lawrence Berkeley National Laboratory. She typically finds bits of biodegradable plastic within the compost she picks up for her mother and father’s backyard. Most biodegradable plastics go to landfills, the place the situations aren’t proper for them to interrupt down so that they degrade no quicker than regular plastics.

Embedding polymer-chomping enzymes in biodegradable plastic ought to speed up decomposition. But that course of typically inadvertently types probably dangerous microplastics, which are showing up in ecosystems across the globe (SN: 11/20/20). The enzymes clump collectively and randomly snip plastics’ molecular chains, resulting in an incomplete breakdown. “It’s worse than if you don’t degrade them in the first place,” Xu says.

Her workforce added particular person enzymes into two biodegradable plastics, together with polylactic acid, generally utilized in meal packaging. They inserted the enzymes together with one other ingredient, a degradable additive Xu beforehand developed, which ensured the enzymes didn’t clump collectively and didn’t disintegrate. The solitary enzymes grabbed the ends of the plastics’ molecular chains and ate as if they have been slurping spaghetti, severing each chain link and stopping microplastic formation.

Adding enzymes often makes plastic costly and compromises its properties. However, Xu’s enzymes make up as little as 0.02 % of the plastic’s weight, and her plastics are as sturdy and versatile as one usually utilized in grocery baggage.

The technology doesn’t work on all plastics as a result of their molecular constructions differ, a limitation Xu’s workforce is working to beat. She’s filed a patent software for the technology, and a coauthor-based startup to commercialize it. “We want this to be in every grocery store,” she says.